|

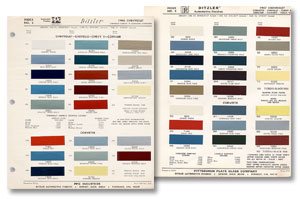

I've got the Blues...

Last issue of Colin’s Corner, I introduced you to my project

vehicle—a 1969 Buick Special (entry level Skylark). The

car is painted a beautiful shade of what I would call a “medium

silver-blue”. Technically speaking, it’s known as

“Crystal Blue” (code 53). I can’t tell you

the number of people who swear up and down that it’s called

“Marina Blue”. No, I tell them, it’s a Buick

color, not a Chevrolet hue. I usually get a look that says “you

don’t know your colors, man”.

Working at OPGI for more than a few years, one develops a pretty hefty

knowledge base of the GM-A Body cars. At Original Parts Group,

we have to be experts in the field—after all, what good

is it when a customer can’t rely on you for accurate information?

We deal primarily with restoration and performance parts and

accessories, so the subject of paint colors and codes doesn’t

come up that often. But when it does, somehow Marina Blue always

enters the conversation. It’s just one of those colors.

I remember being at a big OPGI-sponsored car show a few years

back. It was an all-GM show (of course), with just about every

brand of The General being present. I came across a couple of

guys gushing over a pretty blue ’65 Impala. “Marina

Blue - awesome color” I heard. Wrong-o. I also remember

a buddy of mine, years ago, telling me that his buddy had a

’70 Cutlass in Marina Blue”. Mmmm, sorry. I’ve

even heard “knowledgeable” friends say they’ve

seen ’68 and ’69 Chevelles in MB. Seems this color

sure did get around a lot! Colin’s Corner Truth be told,

the Marina Blue name is reserved for the Bow-Tie brand. And

only for 2 short years: 1966 and ’67. Sure, Chevrolet

was leading up to MB in ’65 with Nassau Blue and even

Mist Blue. Marina Blue (GM code F) was officially introduced

in 1966 models of full-size Chevrolet, Chevelle, Chevy II and

Corvair. The Corvette got Nassau Blue - close. In ’67,

MB was available on all Chevy models - full-size, Chevelle,

Chevy II, Corvair, Camaro, Nova SS and Corvette.

In 1968, the closest color to MB Chevrolet produced was Tripoli

Turquoise. 1969 saw Azure Turquoise. 1970-’72 was Mulsanna

Blue, getting ever further away from the legendary Marina Blue.

Other GM marques had their own “versions” of MB.

In 1967, Pontiac had Tyrol Blue (code F). In 1966 and ’67,

Buick offered Blue Mist (code F), and in ’67 your could

order Ermine Blue (also code F) on an Oldsmobile.

Of course, the really cool thing about paint colors back in

“the day” was the variety. Just for a little time

trip, log onto www.autocolorlibrary.com sometime. Check out any of the GM brands from the 1960s and early ’70s. Just about every year offered

at least 3 or sometimes even 4 different shades of blue. Compare

that to today’s offerings. Blue? Sure, probably. But just

oneshade, hey, let’s not get carried away!

|

| |

|

Headlight bezel re-furb...

Headlight bezels are one of those items that are literally “out

there”. Out there, at the front of your car, taking the

hits. Stone chips and dings can make your otherwise beautiful

car look like a road weary warrior.

Sure, if you own just about any year Chevelle, OPGI has fresh

new factory-correct headlight bezels for your ride. But, if

your car is a little more off the beaten path - like my project

’69 Buick, new bezels aren’t on the menu, yet. In

this installment of Colin’s Corner, I’m going to

show you how I took the budget approach to re-finishing my existing,

tired and beat up headlight bezels. Costs to do this are at

a minimum (we all like that part); all it requires is a little

time and effort and you’ll be ready for the car shows

again!

|

I knocked down the majority of those pitswith a nice combination of

sanding materials. I started with 150 grit Emery Cloth,

then moved to 320 grit waterproof sandpaper, then to a super-fine

600 grit. Some of the deeper, stubborn pits in my headlamp

bezels I was able to smooth out faster with steel wool.

I started with a coarse #1 grade, then moved to a #0 grade.

Very labor intensive,but worth every gnarled fingertip.

Satisfied

that I had all the pits filed flush,

I proceed to the masking stage. Using

3M’sBlue painter’s tape, I carefully

masked off everything except the

outer part of the bezels.

Before

applying paint, I took a cloth

dabbed in some Simple Green De-greaser

to the bezels (to avoid fisheyes in

the paint). I took the bezels outside and applied 3 light

coats of Rust-oleum

Semi-Gloss Black (#7798). Each day,

for the next 2 days (waiting 24 hours between coats), I

re-applied until I had a nice,smooth overall coating.

After letting the outer black area of the bezelsdry solid as a rock (48 hours), I

mask off tha tarea, and of course the raised, chrome platedsections, and

prepare to paint the inner areas that surroundthe headlights.

Using

Rust-oleum’s “Aluminum” spray paint

(#7515),

I hit the inner bezels with a few

light coats. Let dry for 24 hours. Repeat, taking care to

cover every nook and cranny.

To “knock-down” some of the

Aluminum paint’s brightness, I hit the

whole area with a very light “dusting”

of Rust-oleum’s Smoke Gray (#7786).

The masking tape is VERY carefully

removed. Go slow!

The

finished bezels look pretty much factory fresh. Granted,

I haven’t taken

out every last remaining sign of pitting, but I’ve

come pretty darn close. Hey, spend $700-$800 with the pros,

or do it yourself and get 99% there for cheap - your choice.

The refurbished

bezels are re-affixed and look terrific. Should be good

for another 40 years!

|

|

|

How to install a cowl induction system

Does a working cowl induction system add more horsepower to

your Chevelle? Actually, no. But it sure looks awesome, and

it’s doesn’t require years of wrenching experience

to install.

Whether your car was originally cowl induction equipped or not,

we’ll show you how to install the complete system. In

a few hours, with some basic tools, you’ll be flashing

warning signs to all the other muscle on the street.

|

|

All of the parts we’ll need are available from Original Parts

Group: hood, cowl induction door assembly, hood screen, air

cleaner spacer, cowl induction air cleaner assembly, a/c intake

relay, a/c wing nut, vacuum actuator, vacuum actuator support,

c/i wiring harness, firewall grommet, valve frame kit, air control

switch and bracket, flow control valve, hood pins (if desired).

Tip: Whether you’re using your existing

cowl equipped hood or a brand new one, you should remove the

hood from the car and place it upside down on a firm level surface,

at least a foot off the ground. You can install the system with

the hood still attached, but it’s much easier when removed.

Hood removal is very simple, and you will need two people to

do it. Unscrew the 4 bolts that retain the hood to its hinges,

and carefully lift.

First, a few words of advice and precautions:

-

A cowl induction system can be installed on any ’70-’72

Chevelle that is equipped with a four-barrel carburetor. This includes the following engines: 350, 396 and 454.

-

You’ll want to prime and paint your hood before

installing the cowl system. Be sure to paint the cowl door and

screen body color.

-

Be very careful working around the underside of the

hood. It is stamped sheet metal, and all the edges are very

sharp!

-

When reinstalling the hood, make sure you line it up

correctly on its hinges. This is done by lightly tightening

the bolts, then gently shutting the hood to check

for fit. Once you’re satisfied, tighten all 4 bolts with

a socket wrench.

In our first step, we’ve inserted the valve frame cage

flap into the valve frame cage using the 3 supplied retaining

clips. We’ve also inserted the electric solenoid into

its pre-attached retaining bracket. All the parts necessary

for this step are included in OPGI’s “complete valve

frame setup”.

With the cowl induction hood placed upside down on a firm surface

and raised off the ground, insert the assembled valve frame

setup into the hood opening. Secure with the 6 supplied self-tapping

screws using a 5/16” socket wrench.

Next, we insert the firewall grommet into the pre-stamped hole

in the hood, and feed the tan colored wire from the wiring harness

through the grommet. Then, attach the tan colored wire terminal

to the solenoid. You will access the solenoid through the large

air cleaner hole in the center of the hood.

Now we will assemble the hood door. Attach the 2 door supports

(one at each side of the hood door) using the supplied bushings

and pivot screws. The cowl induction hood door assembly kit

is available from OPGI. Even with the screws fully tightened,

the door supports will feel loose and not really firmly connected

to the hood door. This is normal, as the hood door must be allowed

to open and close freely.

Now that the hood door is assembled, we’re going to install

it into the hood. Lay the hood door into the pre-stamped hole

in the hood, and attach it by screwing 4 (2 each side) 3/8”

self tapping bolts through the hood door supports. NOTE: due

to irregularities in metal stampings, you will need to shim

the door supports (using washers) in order to properly align

the hood door. Look under the hood (actually, on top of the

hood) and make sure that you shim the door so that it sits flush

with the hood surface!

Before you finally tighten down those door supports, make sure

the hood door is able to open and shut freely! There should

be at least 1/16” of clearance between the door and the

actual hood. Don’t forget to take into consideration the

thickness of new paint!

Next, insert the vacuum actuator into the vacuum actuator support

and fasten to the hood using 4 1/4” self-tapping bolts.

Then, attach the vacuum actuator “throw” to the

cowl hood door using the supplied screw.

Now that we’ve got all the hood hardware in place, we’re

going to attach the cowl hood screen to the rear of the hood

opening using 8 self-tapping screws. This will keep out those

pesky leaves and unusually large bugs!

Because there’s no vacuum in the system yet, the door

will remain in its open position.

You may be wondering why your ’70-’72 A-body has

three big gaping holes in the cowl grille area (just below the

windshield). Well, they’re obviously for air flow, but

for some strange reason the factory left them open and unprotected.

To keep out leaves and other extraneous junk, you may want to

invest in a set of cowl grill inserts (also available from Original

Parts Group). They simply snap into place.

The entire hood should be reattached to the car at this point.

Have a friend help, and take your time to make sure both sides

of the hood align properly with the fenders.

Now we’re going to get the whole system activated. If

wire routing and switch installation intimidate you, you’re

in for a treat here. This is a pretty simple set-up. Just follow

along.

Attach the air cleaner intake valve relay assembly to the firewall

using a #10 self-tapping screw. This unit sends a “hot”

signal from the wiring harness to the cowl induction solenoid.

There’s a black colored “plug” located in

the firewall just behind the engine’s valve cover. Pop

it open and insert the pink and brown colored leads from the

wiring harness, as well as the braided section of wire. The

pink and brown leads will feed down and attach to the air control

valve solenoid switch, which we will install at the gas pedal.

The braided section of the wiring harness will also feed down

and attach to the car’s existing wiring harness. At the

gas pedal, you will need to remove the existing retaining plate.

Attach the air control valve solenoid switch to its bracket

using the supplied screw. Now fit the bracket to the existing

holes where you removed the retaining plate before. The protruding

post on the side of the solenoid switch will press against the

gas pedal linkage upon full throttle acceleration, actuating

the vacuum and opening the cowl hood door.

Attach the pink and brown wire leads to the terminals on the

solenoid switch (the fitting shape will be obvious), and attach

the braided section to the existing wiring harness under your

dash. This last connection will provide power to the entire

cowl induction system.

Back in the engine compartment, plug the 2 remaining short wires

into the air cleaner intake valve relay assembly (again, the

fitting shape will be obvious). Now route the tan colored wire

(that attaches to the electric solenoid we installed at the

beginning of this project) through the wiring sheath on the

firewall to protect it.

You’ll need to place the cowl induction spacer assembly

on top of the carburetor. This ring simply sits atop of the

carb, and allows the air cleaner to sit up a little higher,

into the cowl hood.

Attach the cowl induction air cleaner flange and seal kit (part#KC1500

black lid) or (part#KC1501 chrome lid).

Now you’ll have to fit a 1/4” rubber hose (not included

in kit, but available from any auto parts supply store) to the

vacuum actuator. Then route the hose to fit the other end to

the vacuum port located on the intake manifold just behind the

carburetor. The vacuum port is standard on all Chevelles, as

it is used for other vacuum operated accessories.

Fire it up and grab a few shifts. Watching that cowl door open

under full throttle makes it all worthwhile!

|

Pic 1: The cowl induction system on this Chevelle is straight out of 1970. You can see the valve frame setup in the hood opening.

Pic 2: The 1/4” rubber hose attaches to the vacuum

actuator. The other end routes to the vacuum port located

on the intake manifold just behind the carburetor.

Pic 3: At rest, the hood door is supposed to stay open, because

there’s no vacuum in the system.

|

|

|

The First Hurst/Oldsmobile

Ever hear the story of how the first Hurst/Olds came to be?

It’s a good one. I’ll give you the Cliff’s

Notes version here: Back in 1968, John Beltz, Oldsmobile’s

chief engineer, wanted to boost the performance image of his

division’s A-Body. Hurst-Campbell and Mr. Beltz got together

and decided to slip a batch of “breathed on” Toronado

455s V8s between the fenderwells of 515 Cutlass 4-4-2s. With

Hurst installing the mega-motors, not Oldsmobile, they had squirmed

around GM’s corporate edict banning engines of more than

400 cubes in the GM intermediate body style.

But it was already the end of April, 1968, and very close to the end

of the model year production. The H/Os had to be built and shipped

out to dealers in time to serve as end-of-the-year traffic builders.

If the cars arrived in showrooms after the ’69s were out,

they would be of no use to Oldsmobile. Lansing industrialist

John Demmer provided warehouse facilities in which the cars

were built; a crowded, makeshift assembly line was forged and

local suppliers were put on full scale alert. Amid cries of

protest from the marketing folks at Oldsmobile, 515 Peruvian

Silver H/Os were hustled together in just under a month. Marketing

thought the entire program was a complete waste of time and

money, claiming the cars would never sell. Two days after Olds

announced the availability of the car, more than 900 orders

came pouring in. The next day the order tally hit 2600! Supply

and demand was seriously out of whack, and a lot of dealers

were left out in the cold. The ’68 Hurst/Olds stepped

into the history books as the rarest H/O ever produced.

Cranking out 390 horsepower and a road-ripping 500 ft.lbs. of

torque, this firebreathing musclecar could chew up just about

anything on the road. With a 10.5:1 compression ratio and 3.91:1

gears harnessing all that torque, the H/O was good for mid-13

second quarters all day, all the while lavishing its cargo in

traditional Olds comfort and prestige.

The ’68 Hurst/Olds was the first and fastest in a long

line of legendary Oldsmobiles produced in conjunction with the

Hurst-Campbell company. Only 515 of these cars were built. After

the ’68 model year, all future H/Os would increase in

production, and decrease in power. Lowest production numbers,

an understated appearance package, and a rated 390 horsepower

make the first H/O the most collectible of all.

If you happen to be restoring one of these beasts, or are thinking

about possibly turning your Cutlass into an H/O clone, keep

in mind Original Parts Group has pretty much every restoration

part you’ll need to get the job done. Of course, OPGI

stocks all the “standard” Cutlass restoration items

(inside and out), but we also carry the more unique stuff -

from H/O deck lid and fender emblems (for the ’68-’72

cars), to those cool bright red inner fenderwells!

|

|

|

Top 5 little known facts about the first Hurst/Olds

-

Of the 515 cars built, 459 were Cutlass Holiday 2-door

hardtops. 56 were 2-door post coupes.

-

All 515 ’68 H/Os were hand pinstriped by one man;

Paul Hatton. Hatton did them all in one month, and

charged $20 per car. That’s over $10,000 for one month’s

work!

-

The 455 cubic-inch engines were pulled directly from

the Toronado line, and were purposely assembled

with incredibly loose piston clearances of 3-4 thousandths of

an inch.

-

Only the first car was equipped with a 4-speed manual

transmission. It ran the 1/4 mile in 12.97 sec.@108

mph. All other ’68 H/Os came with the TH400 auto and the

Hurst Dual Gate Shifter.

-

All were painted Peruvian Silver (code ZZ); a “Toronado

only” color.

|

|